GASKETS AND SEALING

Bay Area Gasket and Supply provides a comprehensive range of gaskets, gasket materials, and sealing products to meet industrial, hydraulic, and OEM needs, including custom-cut and stock gaskets in rubber, PTFE, compressed non-asbestos, graphite, cork, and specialty composites; full sheets and rolls of gasket material for field fabrication; precision waterjet-cut gaskets for complex profiles; flange gaskets, O-rings, seals, and kitting for preventive maintenance programs; and complementary sealing accessories such as sealants, adhesives, washers, and fasteners. We fabricate custom gasket solutions to drawing or sample, support rapid turnaround for emergency repairs, and offer technical guidance on material selection and compatibility with fluids, temperature, and pressure to ensure reliable sealing performance across oil, chemical, steam, and hydraulic applications.

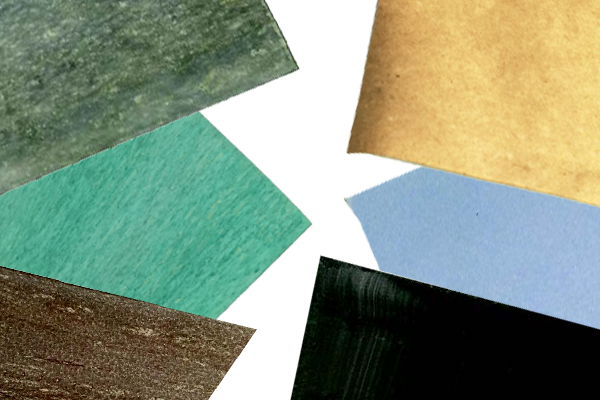

SEALING MATERIALS

Bay Area Gasket and Supply offers a comprehensive selection of quality gasket materials engineered to meet the demands of industrial, hydraulic, and marine applications, including elastomers (NBR, EPDM, Viton), compressed non-asbestos sheets, PTFE, graphite, cork-rubber, and multilayer steel for flange connections. Materials are sourced from trusted manufacturers and stocked in standard and custom thicknesses, with in-house waterjet cutting and CNC die-cutting to produce precise, repeatable gaskets from customer drawings or on-site measurements. Technical guidance on material compatibility, temperature and pressure ratings, and sealing performance is provided by experienced staff, and rapid prototyping, small-batch runs, and full production quantities are supported to ensure reliable, cost-effective sealing solutions for repair, maintenance, and OEM needs.

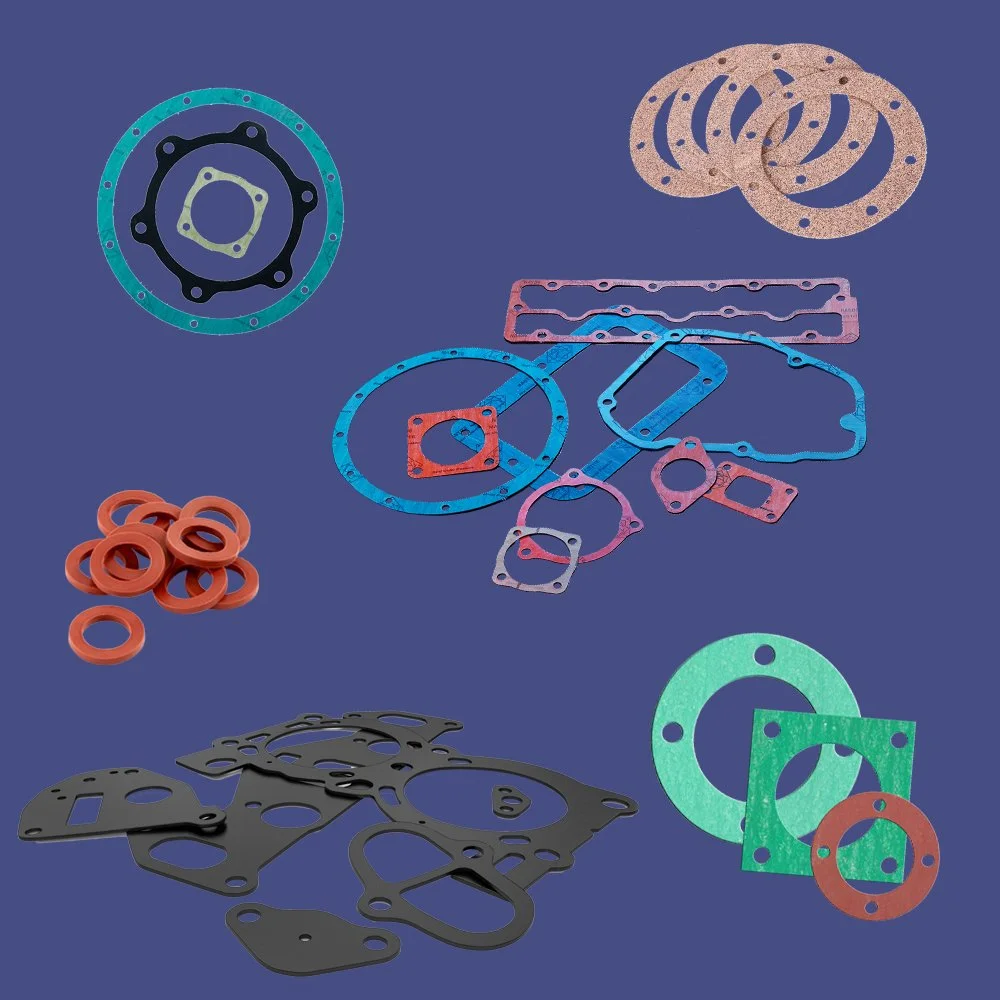

GASKET MAKING

Bay Area Gasket and Supply offers comprehensive standard and custom gasket manufacturing capabilities to meet industrial sealing needs across sectors. We stock a wide range of standard gasket materials and shapes for quick turnaround while also providing custom-cut gaskets using CNC and waterjet cutting for precise tolerances and complex profiles. Our fabrication capabilities include die-cutting, adhesive bonding, skiving, and laminating of materials such as rubber, PTFE, compressed non-asbestos, cork, and composite sheet goods, and we can produce gaskets in thicknesses and surface finishes to suit specific pressure, temperature, and chemical resistance requirements. For specialty applications we design and manufacture custom gasket kits, bonded seals, and multilayer or laminated assemblies, and we perform material selection and engineering support to ensure proper sealing performance. In-house quality checks and prototype runs allow rapid validation before full production ensure gaskets are delivered ready for installation.

OTHER SEALING

Bay Area Gasket and Supply offers a comprehensive selection of O-rings and other dynamic and static sealing products beyond flat gaskets, including metric and inch-size O-rings in Buna-N, Viton, EPDM, silicone, and specialty compounds for chemical resistance and high-temperature service; quad-rings, X-rings, U-cups, backup rings, oil seals, shaft seals, and molded rubber-to-metal assemblies; PTFE and elastomeric custom-molded seals, lip seals, and molded grommets; and a range of spring-energized and braided packing for valves and pumps. We provide custom cutting, molding, and tooling services, in-house material selection guidance, and fabrication to match OEM specifications or create engineered sealing solutions for hydraulic systems, pneumatic applications, marine and food-grade environments, and industrial process equipment. Inventory support, quick-turn custom assemblies, and technical assistance ensure the right material, durometer, and tolerances for leakage prevention and long-term reliability.